Factory Certified GT-20 (NEW LINING)

Factory Certified GT-20 (NEW LINING)

Description

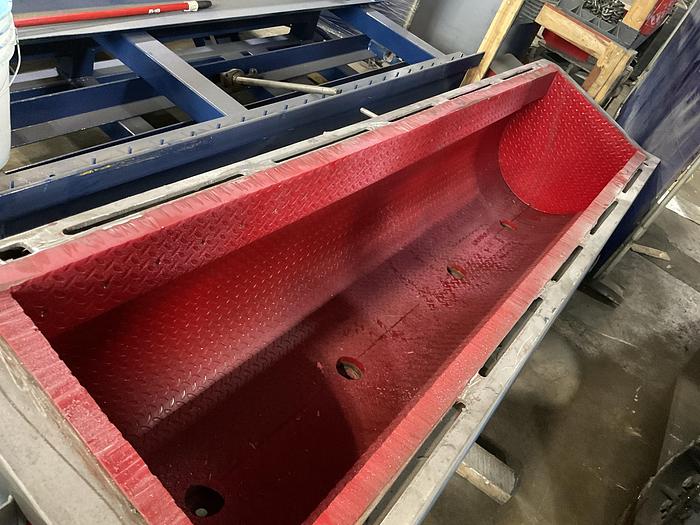

22" x 96" process chamber

Giant Model GT-20 Vibratory Deburring and Finishing Machine, heavy duty design, as described and specified below

SPECIFICATIONS:

Overall Dimensions:

Length……………………………………………………………………………112"

Width…………………………………………………………………………….58"

Load Height……………………………………………………………………...40”

Height……………………………………………………………………………48"

Cubic Capacity ………………………………………………………………….20 Cu. Ft.

Shipping Weight…………………………………………………………………6,080 lbs.

Floor Space………………………………………………………………………45.6 Sq. Ft.

Tub Dimensions:

Diameter of Tub…………………(after lining)………………………………..22"

Length of Tub……………………(after lining)………………………………..96"

Maximum Load Capacity……………………………………………………… 4,500 lbs.

Lining Material………………………………………………………………….1"

Vibration Frequency…………………………………………………………….900-1450 VPM

DRIVE UNIT: 10 HP T.E.F.C. Hostile Duty High Efficiency, 230 volts, 3 phase, 60 cycle motor.

ELECTRONIC VARIABLE SPEED DRIVE WITH DIGITAL TACHOMETER: An AC inverter coupled directly to the motor controls the vibration frequency. Push buttons for increase or decrease of the vibration frequency are in the main panel. A digital tachometer provides a read-out of machine RPM.

MACHINE BASE is manufactured of steel beams and all welded construction for maximum rigidity. Floor mounting pads are furnished for ½ inch floor mounting studs.

VIBRATORY MECHANISM: Balanced Suspension Drive is mounted on extra heavy duty Spherical roller bearings in precision turned housings securely attached to the vibratory tub. This mounting system and the long eccentric weights create even action through the processing chamber allowing continuous duty under the most adverse conditions. The tuned coil springs are mounted on urethane pads and are off-set front to rear allowing a natural rolling action with less input from the eccentric train. This natural action results in extended bearing and tub life cycles. Bearings can be lubricated by an optional automatic fail safe system. Grease is injected into the bearings on a timed basis controlled by an adjustable solid state pulse unit located within the control panel. The vibratory unit is driven by V-belt and pulley arrangement from power unit. Variable amplitude is adjusted manually by adding additional weights to the eccentric bar.

THE VIBRATORY TUB: is constructed of heavy reinforced steel tube gusseted its entire length. The welded structure is stress relieved and shot-peened after welding to prevent fatigue. Rear end of tube is equipped with a plug discharge door, for discharging media into container. Drainage of contaminants from the machine is by means of perforated 1/8" diameter holes at bottom of tube. Effluent flows to drainage hoses leading to effluent container.

JIC CONTROL PANEL U.L. Listed components housed in NEMA type 12 enclosures.

230 voltages are transformed to 110 volts at operator controls. Includes start/stop push buttons, compound system selector switch and plug in receptacle, lapsed hour recorder, 0-6 hour process timer and fused disconnect.

OTHER VOLTAGE IS AVAILABLE UPON REQUEST. CONSULT FACTORY FOR ADDITIONAL CHARGES.

INCLUDED IN BASE PRICE:

1. A.C. Inverter variable speed drive with digital tachometer.

2. Balanced Suspension Drive vibratory mechanism

3. Polyurethane lining.

4. Variable amplitude adjusted manually.

5 Auto Compound System

6. High efficiency motors.

7. Auto Grease System

8, ST-110 Settling Tank

Specifications

| Manufacturer | Giant Finishing |

| Model | GT-20 |

| Year | 2014 |

| Condition | Refurbished |

| Serial Number | 2416 |

| Stock Number | GT-20 |